Incorrect terminology puts a real estate agent or homeowner at high risk.

When putting a home up for sale there are many details that are disclosed, sometimes, in a mandated seller disclosure report and other times for marketing promotions. If these features are overstated or not described correctly, liability and lawsuit risks will rise. There is no greater concern in purchasing a home than a wet basement. As a MN home inspector I too often see water control systems improperly portrayed. So let’s get the vocabulary and description correct.

Sump

The basket or pit that goes into the floor; it is typically about 3’ deep. In extremely high water table situations they can be up to 6’ deep. The sump is required to have a cover that is screwed down to protect kids and pets from drowning.

A plastic or metal diverter that sits on top of the basement floor slab. It is about 4” high and is glued to the foundation on the top and the floor slab at the bottom. Holes are drilled into the blocks allowing them drain and the diverter channels the water to either a floor drain or sump. This is not a drain tile system. It is an inexpensive, non-invasive, low quality method of managing wet basement walls. If the diverter glue fails the basement gets wet.

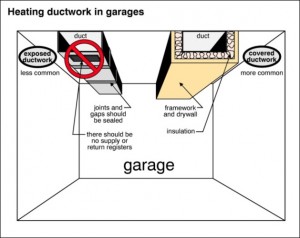

This is either a continuous plastic pipe with holes or clay pipe with open joints. Typically the pipe goes around the entire perimeter of the foundation below the floor slab and alongside the footing. Drain tile can be installed on the interior or exterior of the foundation and the pipes terminate in the sump.

Pump

This is an electrical pump that sits in the sump often called a sump pump. There is also battery pumps used to back-up the electrical pump if the power goes out.

Why is this important?

Can a house have just a sump? Sure, but this is not a drain tiled basement. It is just a basket in the floor. Is the beaver system the same as drain tile? No the beaver system is above the basement floor and the drain tile is below. A beaver system is an inferior method of water control. Can a basement be partially drain tiled or beavered? Yes and this is more common than you would imagine. To call a basement drain tiled you are implying the entire basement and that may not be true. Can a pump be discharged into the laundry tub? No sump pumps must be drain into the city storm drain or onto the yard. There is a stiff fine if caught dumping the water into the homes plumbing system. Does having a sump pump mean the basement is drain tiled? Absolutely not.

If you don’t know what you have, don’t claim it is something it might not be. That would make you easy pickings for a lawsuit.

![]() Doug Hastings

Doug Hastings

MN Home Inspector, Minneapolis & St. Paul

ASHI Certified Inspector, ACI

Kaplan University, Home Inspection Lead Instructor

![]() ‘Pops’ Rob Leslie

‘Pops’ Rob Leslie

Kaplan Professionals, Retired

Follow Cities Inspection’s on Facebook for more home care tips.